Optimize Success at Every Stage of Your Medical Devices’ Lifecycle

Consulting

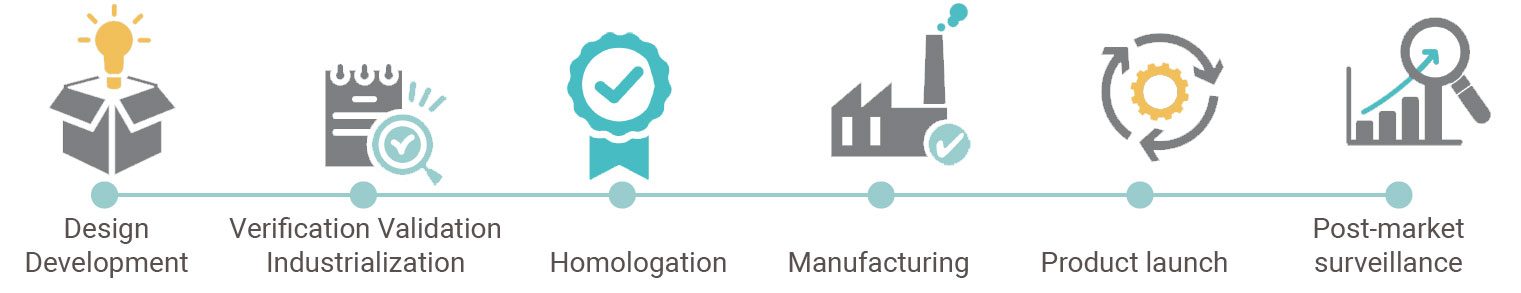

With recognized expertise in the field of medical devices, MedWay Consult offers comprehensive support throughout the entire lifecycle of your medical devices.

Regulatory Affairs & Quality

We handle the development of regulatory strategies and the preparation of the technical documentation required for CE marking (MDR 2017/745) and international registrations, regardless of your medical device’s classification.

Relations with notified bodies and competent authorities are facilitated by preparing and submitting dossiers, managing interactions with these entities, and responding to additional information requests, ensuring a smooth and effective navigation through complex regulatory processes and fostering a relationship of trust.

MedWay Consult also supports you in your company’s quality management system according to ISO 13485 and 21 CFR Part 820, ensuring the effectiveness of the QMS, and overseeing audits, supplier and operational quality, as well as the management of non-conformities, CAPAs, and complaints.

Furthermore, MedWay Consult assists with certification audits and inspections, providing detailed and personalized support. This includes staff training, preparation of the required documentation, as well as assistance during and after the audit to ensure compliance and success.

Design & Industrialization

Benefit from comprehensive and tailored support throughout design and/or change control processes of your medical devices. From the concept phase, close collaboration with your teams helps define specifications and applicable regulatory requirements, also ensuring design for manufacturing. We manage the development of prototypes and conduct thorough testing to verify and validate the functionality and safety of the device, including performance, biocompatibility, and stability evaluations.

A rigorous risk management approach is implemented to ensure not only regulatory compliance but also patient safety.

The transfer to production is streamlined by ensuring the entire manufacturing process is optimized and validated to guarantee productivity and robustness. This includes staff training, control of manufacturing processes, and the establishment of robust quality control systems.

Effective industrial strategies are established to optimize the production of your medical devices, taking into account the specific needs of your business. This approach includes the rigorous definition and validation of manufacturing processes, ensuring their efficiency, reproducibility, and regulatory compliance, as well as the validation of software and test methods.

Our expertise allows us to create and validate robust and optimized production processes, ensuring high manufacturing quality while meeting deadlines and budgets.

We also handle the preparation of design and production documentation (DHF/DMR/DHR/VMP).

Process Optimization and Project Management

Leverage proven experience across various organizations to manage and implement innovative solutions aimed at improving productivity and optimizing the market launch of your medical devices.

Interim Management

With significant experience in the medical device sector, team management, and participation in Management Committees, this interim management service meets the immediate needs of companies.

Whether for a temporary replacement or while awaiting the recruitment of the ideal candidate, this offer allows for the fulfillment of Manager or Director roles in R&D, Quality, Regulatory Affairs, and Industrialization.

The main objectives are:

- Maintain effective management of teams and projects

- Ensure process quality and regulatory compliance

- Provide strategic expertise within the management team

- Optimize existing processes while meeting performance objectives

This solution guarantees a smooth transition, enabling the company to stay focused on its strategic priorities while ensuring continuity and operational excellence during the interim period.

Keypoints of our Expertise

Regulatory Affairs

- Definition and implementation of regulatory strategy

- Deep expertise of CE marking and European regulations applicable to medical devices (MDD 93/42/EEC, AIMDD 90/385/EEC, MDR 2017/745) for all product classes (I to III implantable)

- Creation / maintenance of technical documentation

- Management of international registration, specifically Canada, USA, Brazil, Australia

- Control of reportability and good collaboration with Notified Bodies and Competent Authorities

Quality

- Deep knowledge of ISO 13485 and 21 CFR Part 820

- Creation / maintenance of an effective quality management system

- High expertise of ISO 13485, CE marking, MDSAP audits and FDA inspections

- Management of quality in operations and within suppliers

- Management of non-conformities, CAPA and complaints

Design

- Risk management according to ISO 14971

- Creation / maintenance of DHF

- Validation of device stability, lifetime and shelf-life

- Support Design / Change control processes

- Design verification and validation including biocompatibility according to ISO 10993

Industrialization

- Definition and implementation of industrial strategy

- Control and validation of manufacturing processes, test methods

- Software Validation for manufacturing

- Creation / maintenance of DMR/DHR/VMP

- Change control of manufacturing processes

Project management & Improvement of Operational Processes

- Definition and implementation of strategies and innovative solutions to improve the productivity and efficacy in placing compliant medical devices on the market